Summer 2016

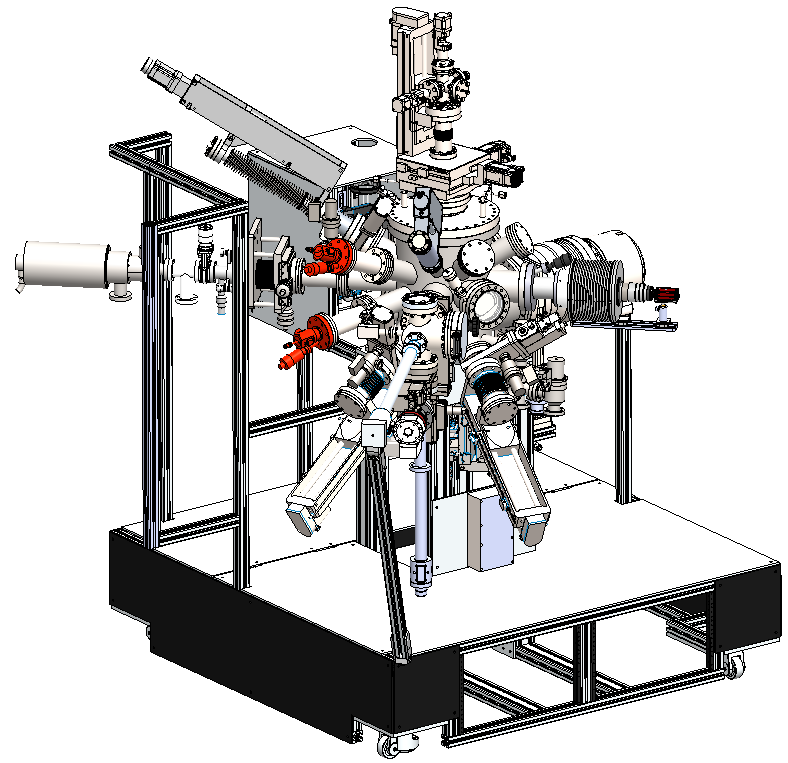

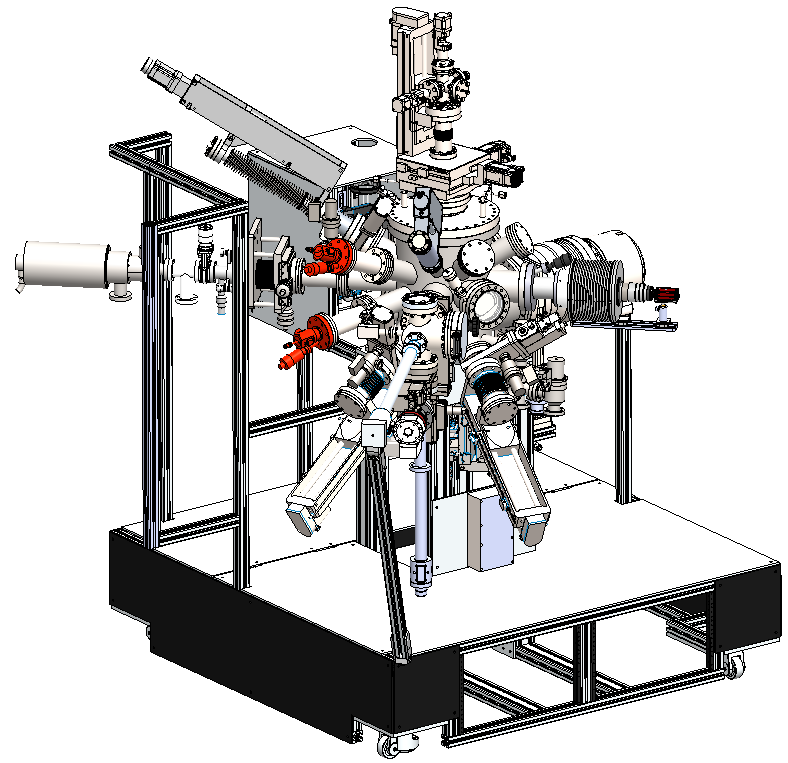

Chamber assembly in SolidWorks

|

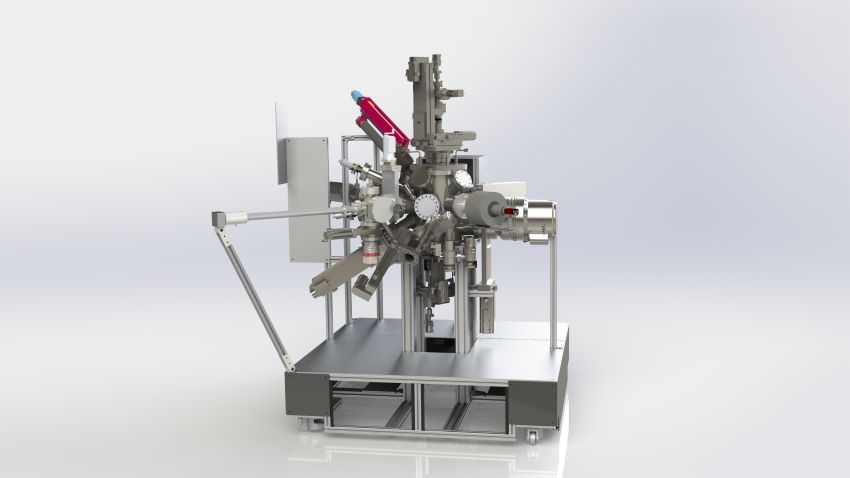

CAD assembly rendered

|

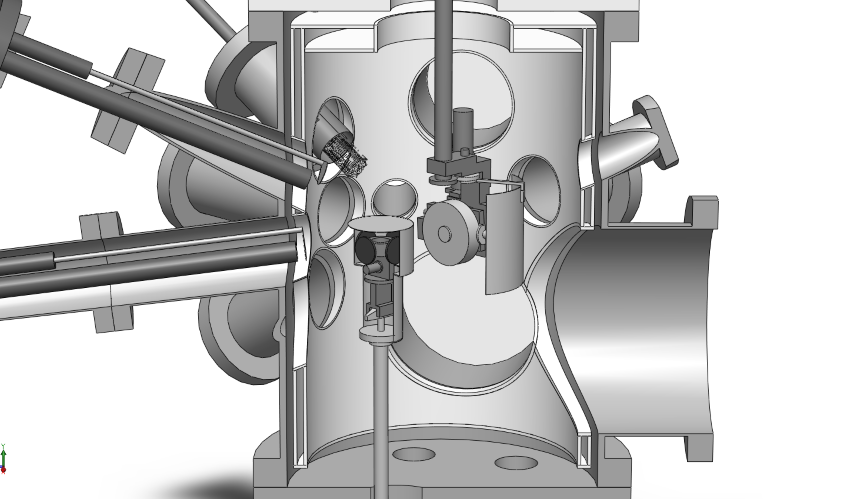

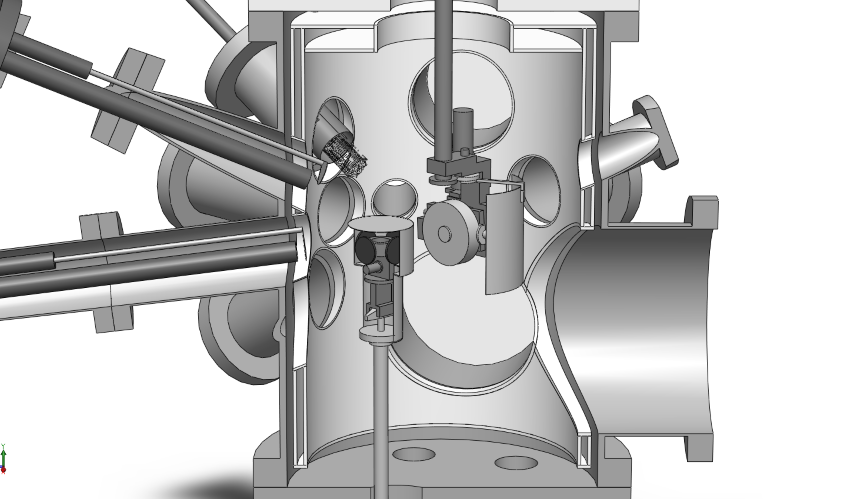

Cross-section of the chamber showing sample holder and target stage as well as the beam flux monitor arm

|

|

December 2016

Recieving new Coherent LPX305 Excimer laser

|

Unboxing diode laser for substrate laser heating system

|

|

February 2017

New Coherent LPX305 Excimer laser (left) installed in lab's utility room. Water, gas, exhaust, and vacuum lines installed

|

|

March 2017

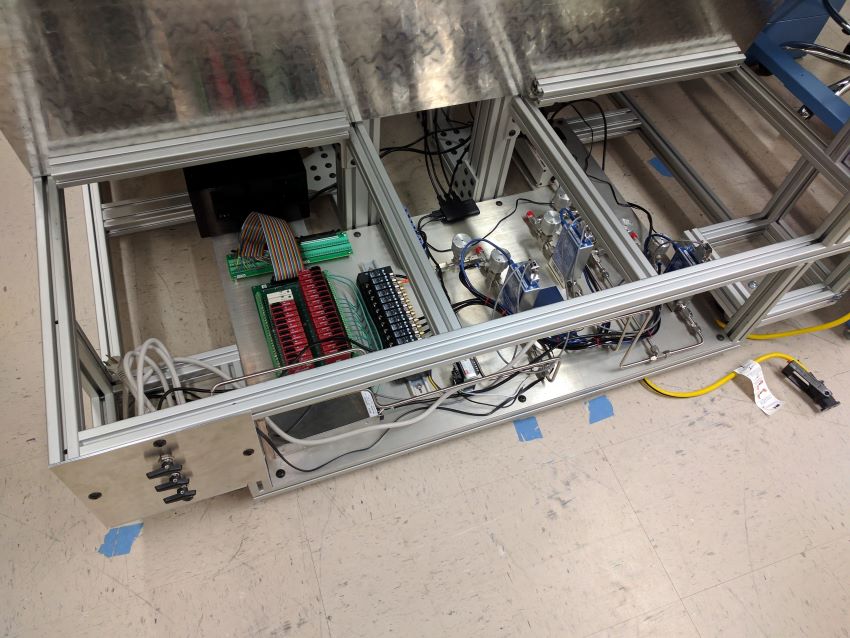

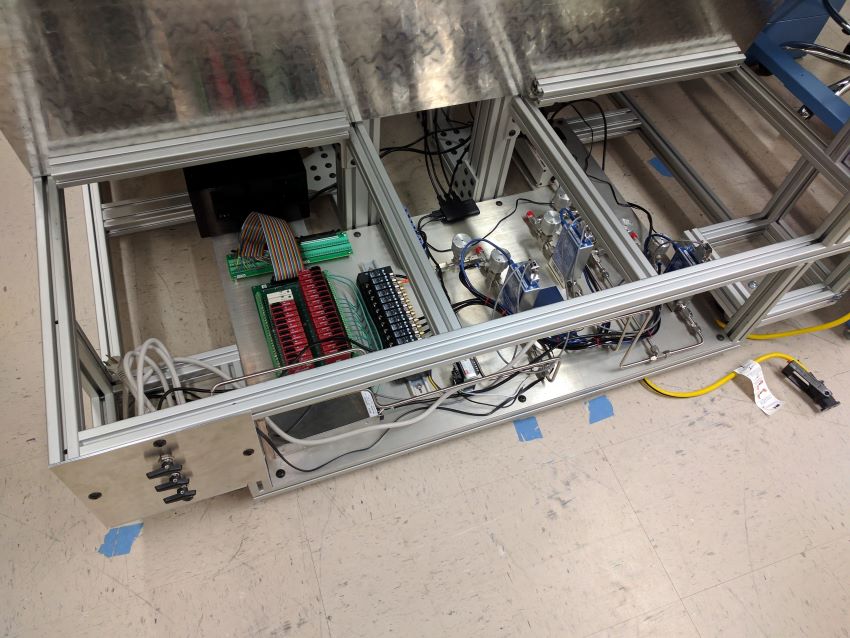

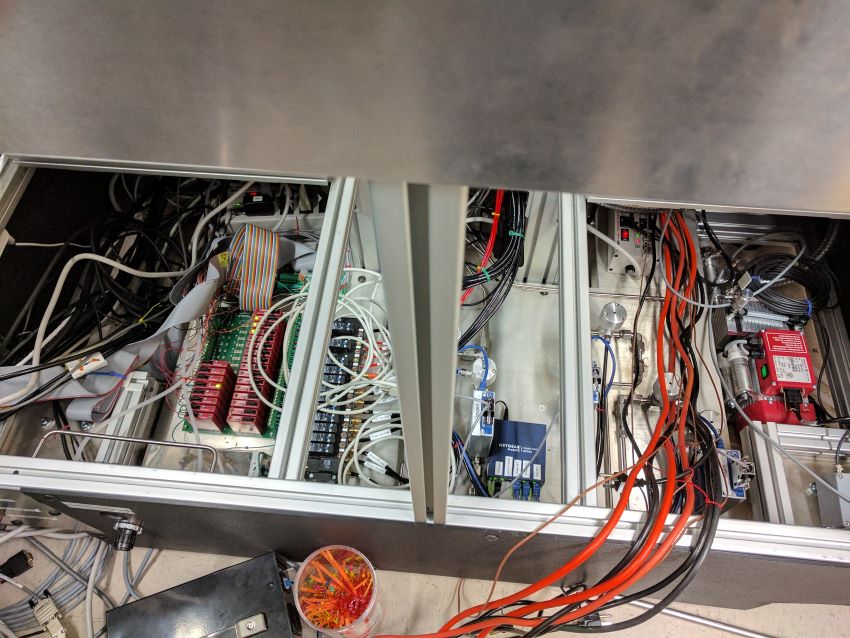

Chamber control board installed into the frame of the chamber

|

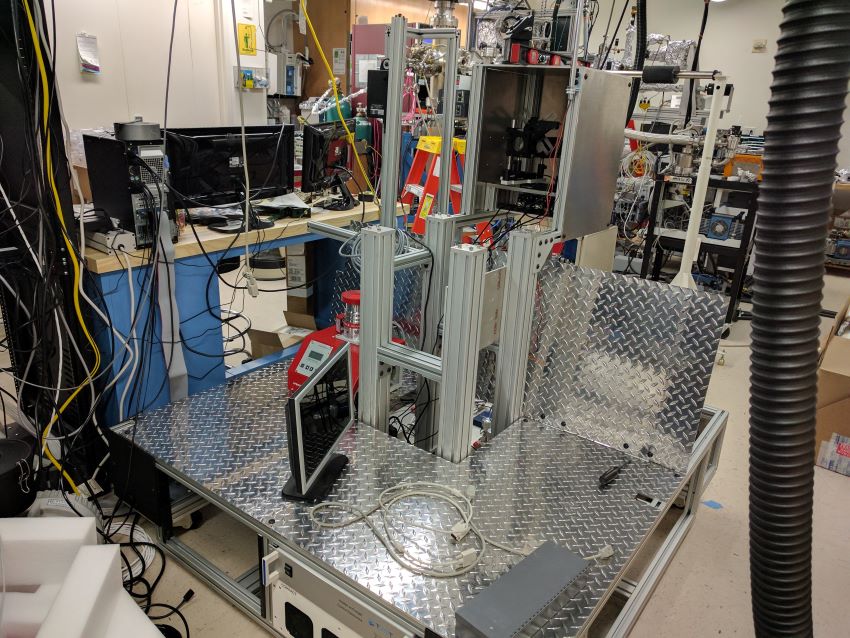

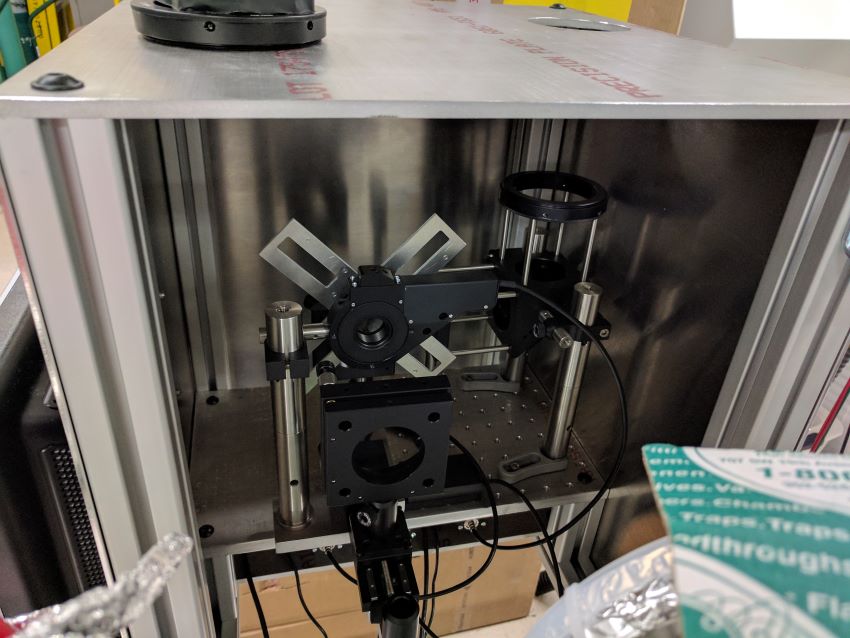

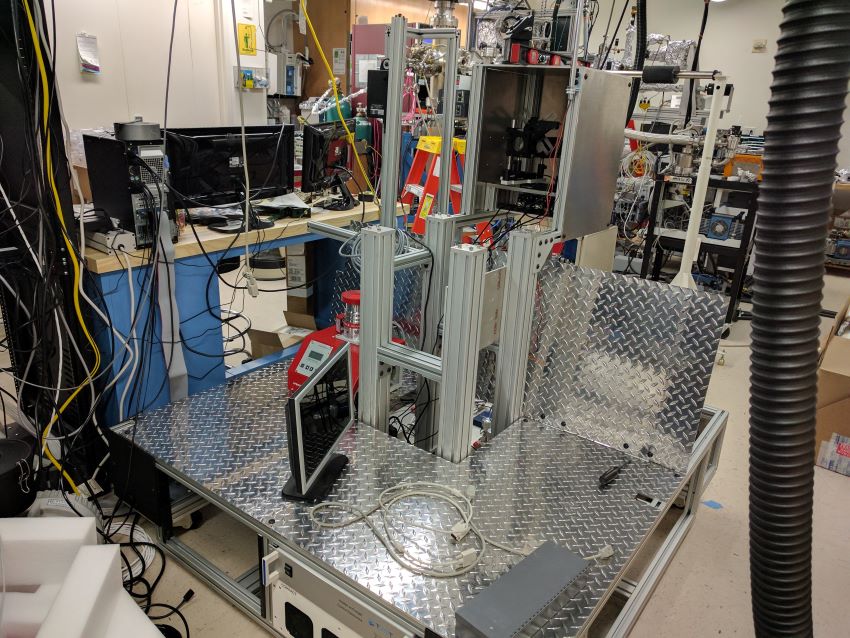

Completed chamber frame and optics box

|

|

April 2017

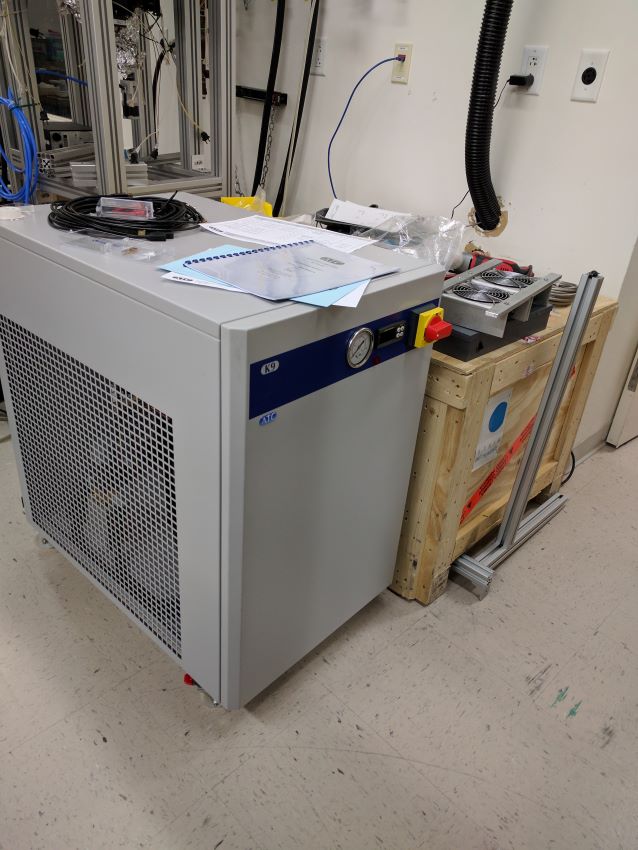

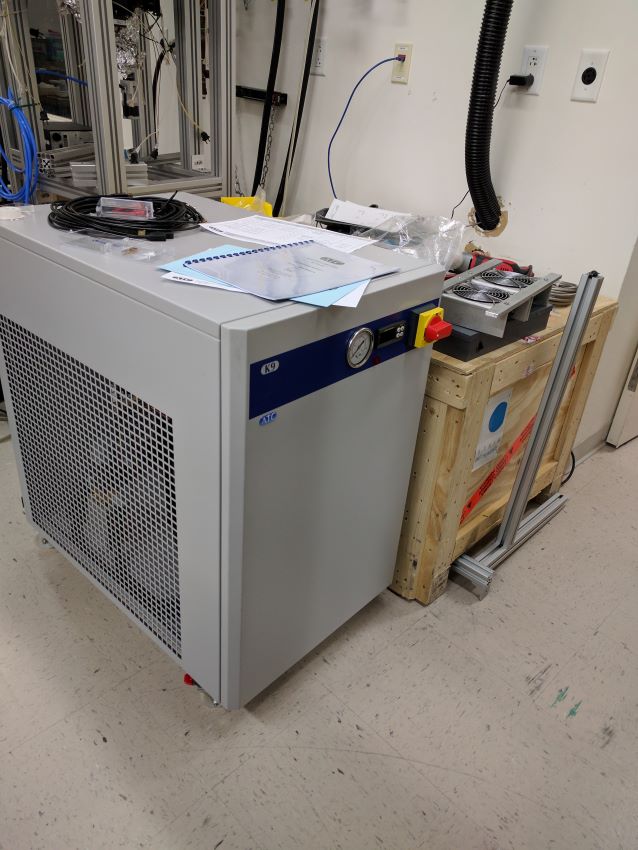

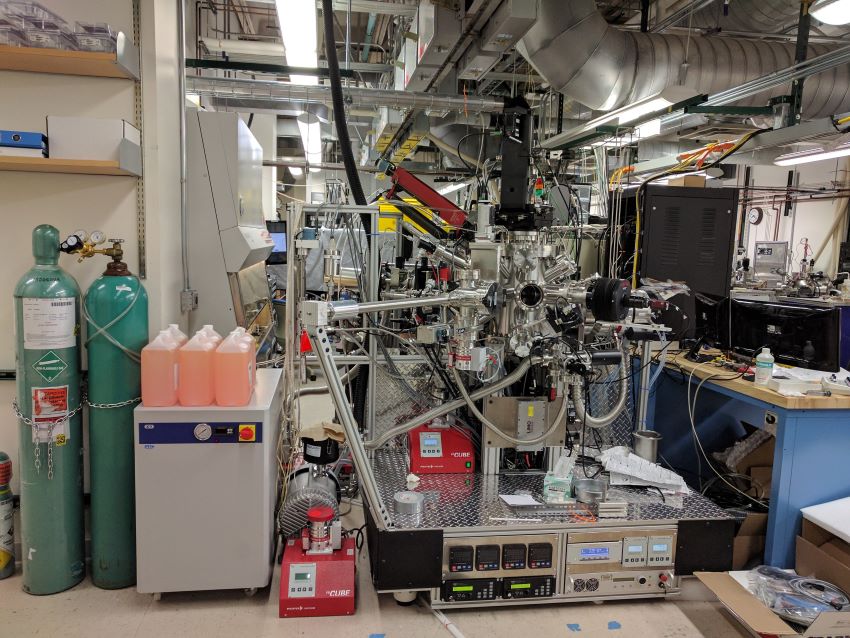

Cryopanel -20C glycol chiller has arrived as well as the Staib RHEED electron source

|

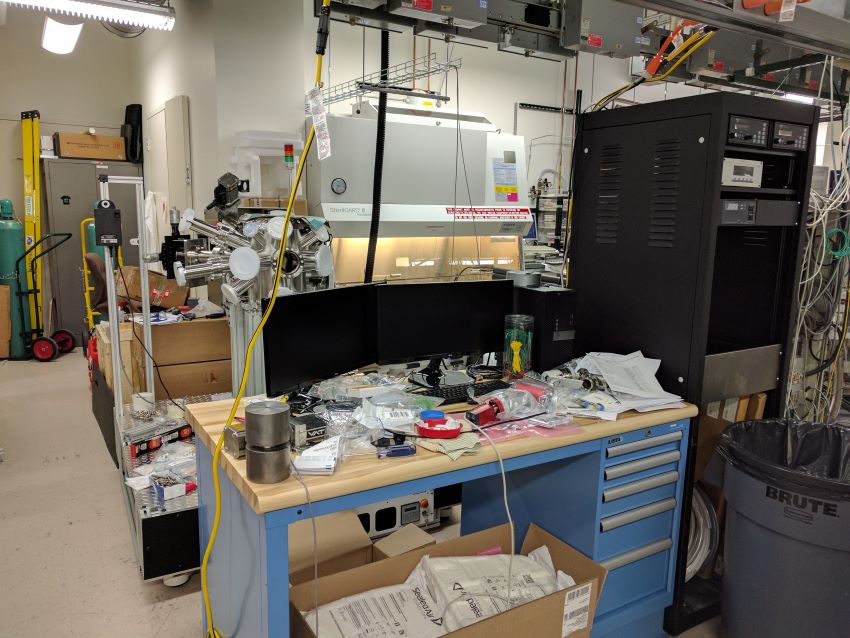

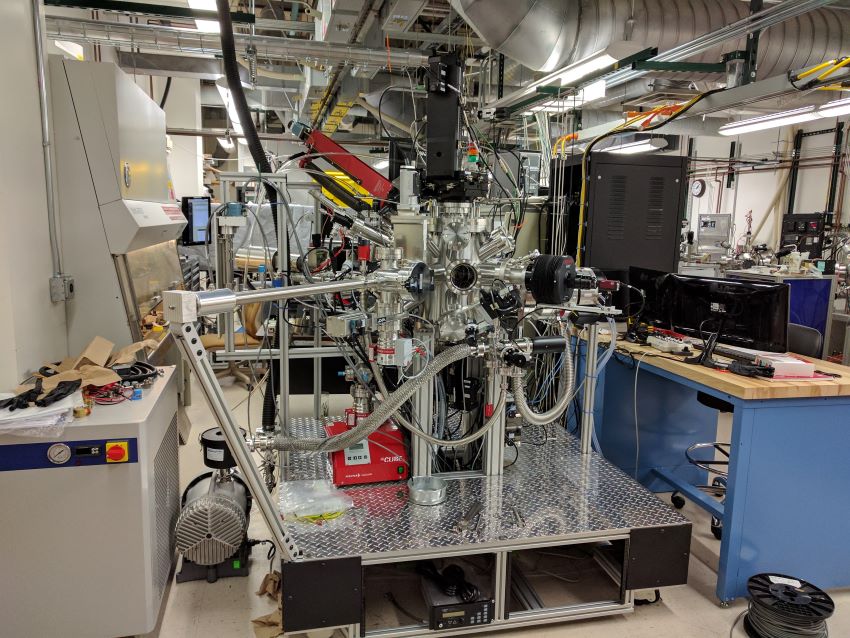

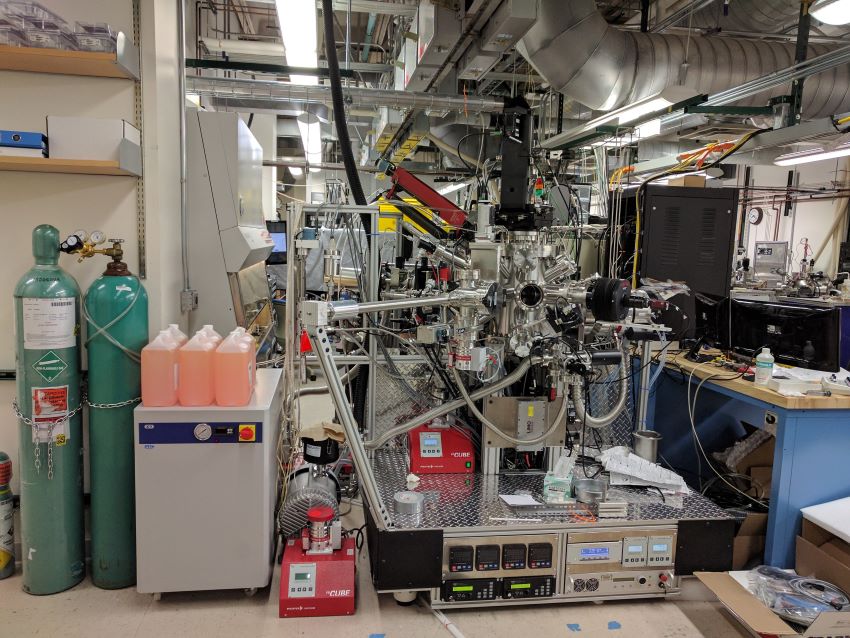

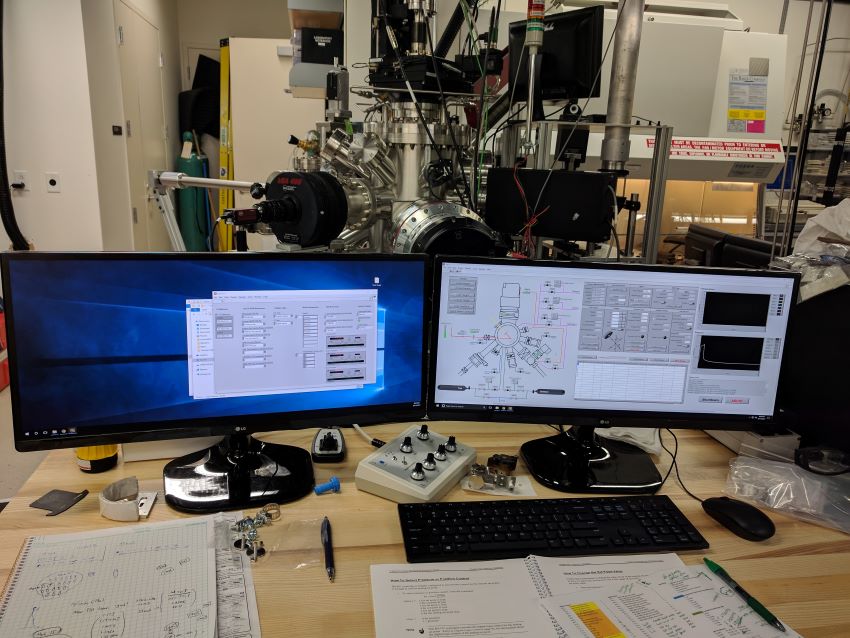

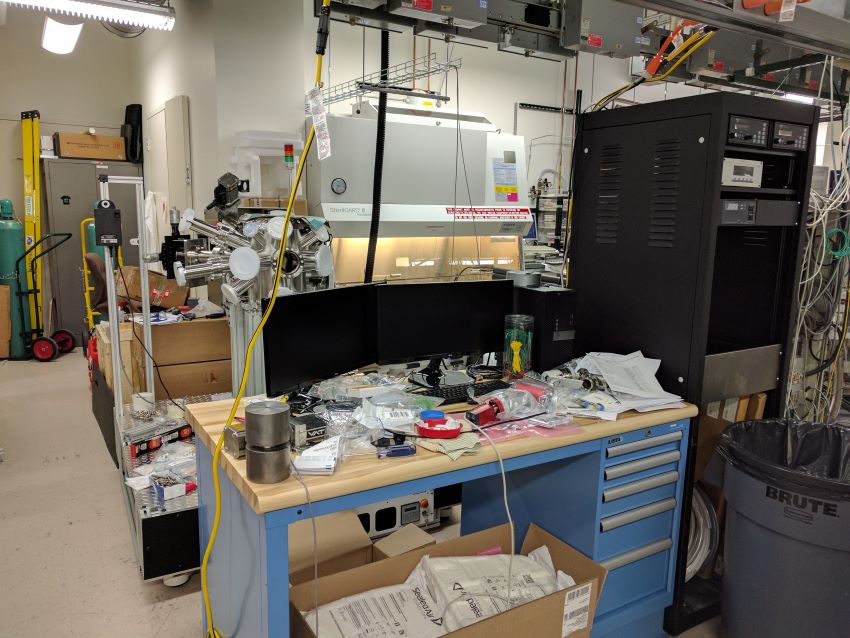

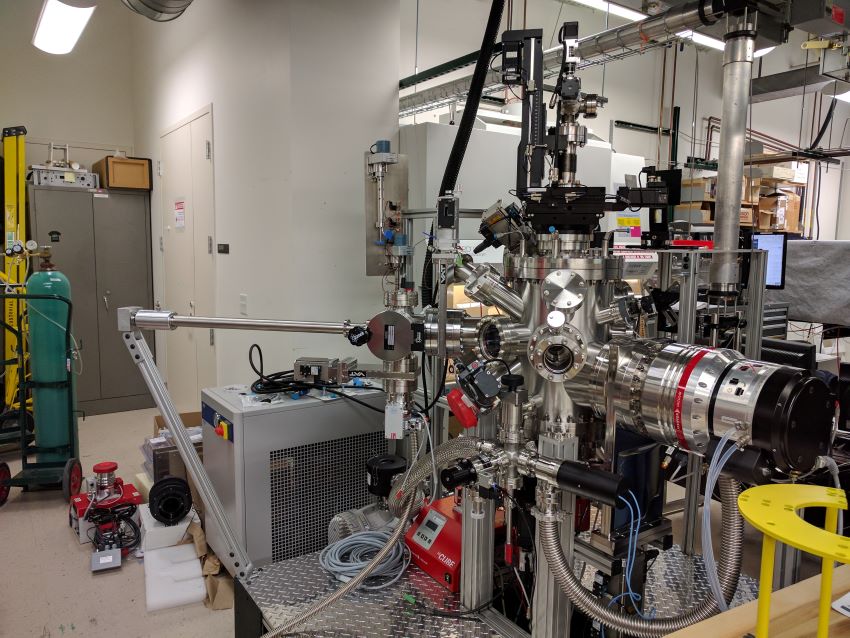

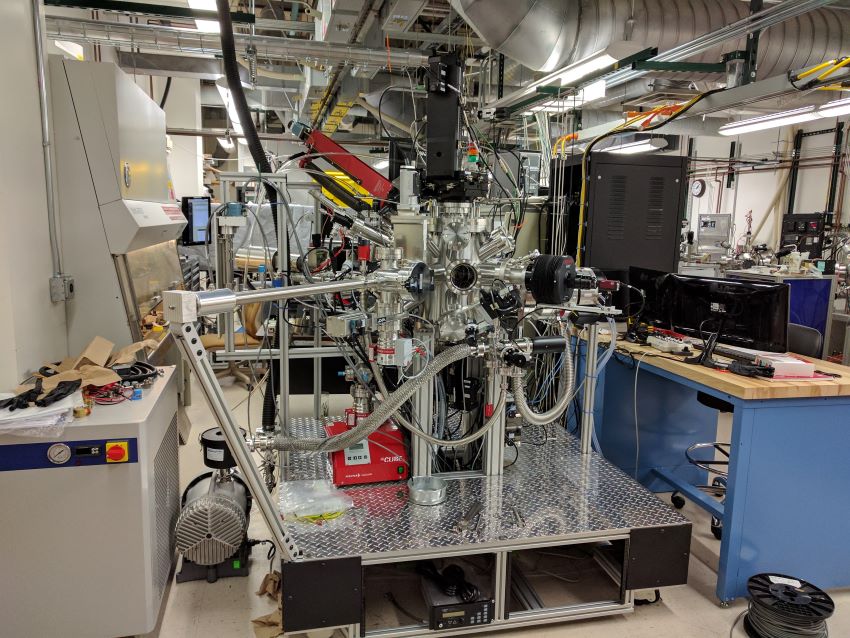

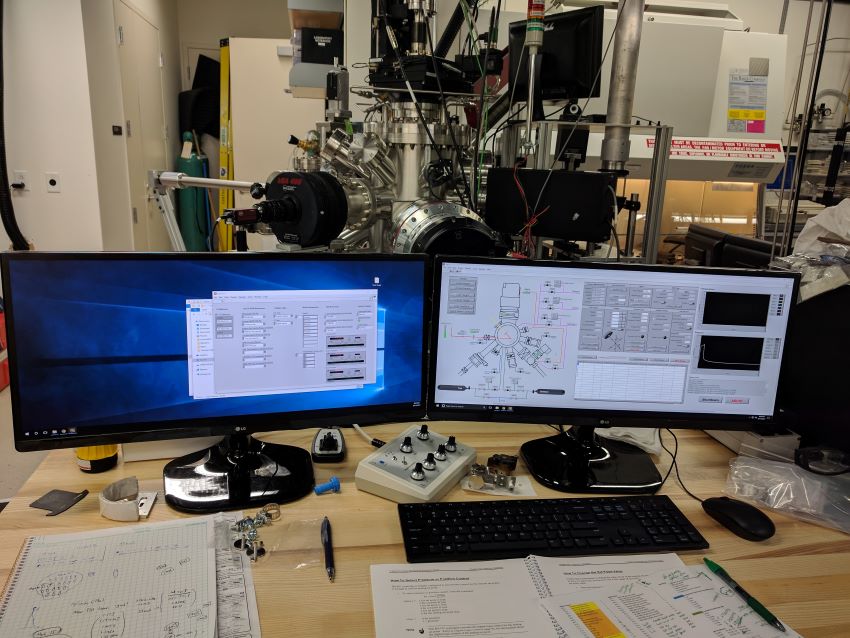

Chamber workstation desk setup along with equipment rack for the chamber. Chamber has arrived and is mounted to frame

|

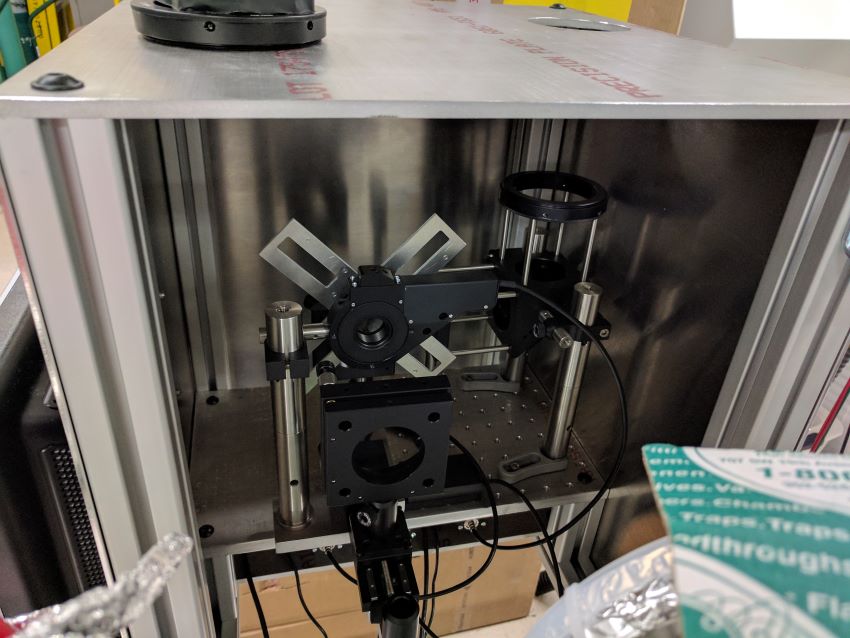

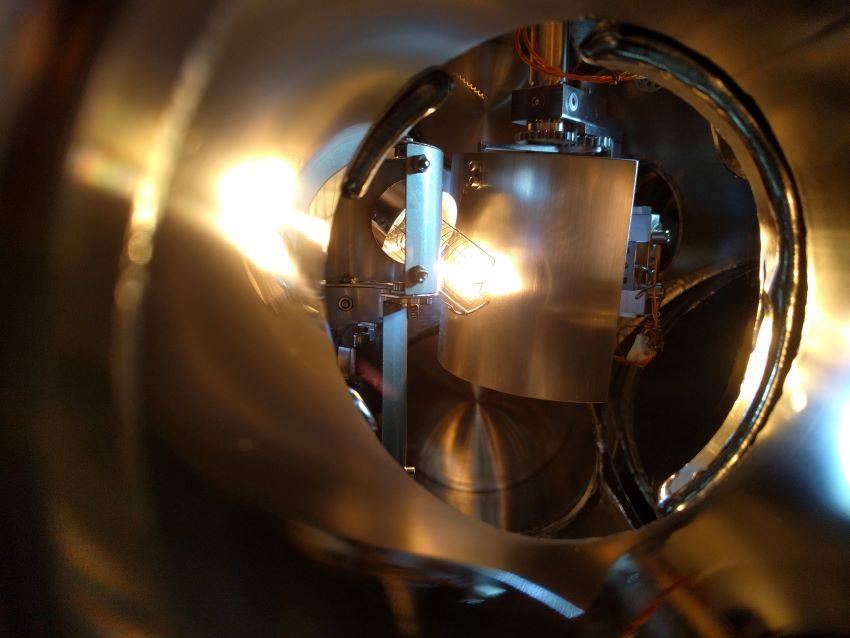

Optomechanics installed (mask changer, laser focus adjust, laser sweep)

|

|

May 2017

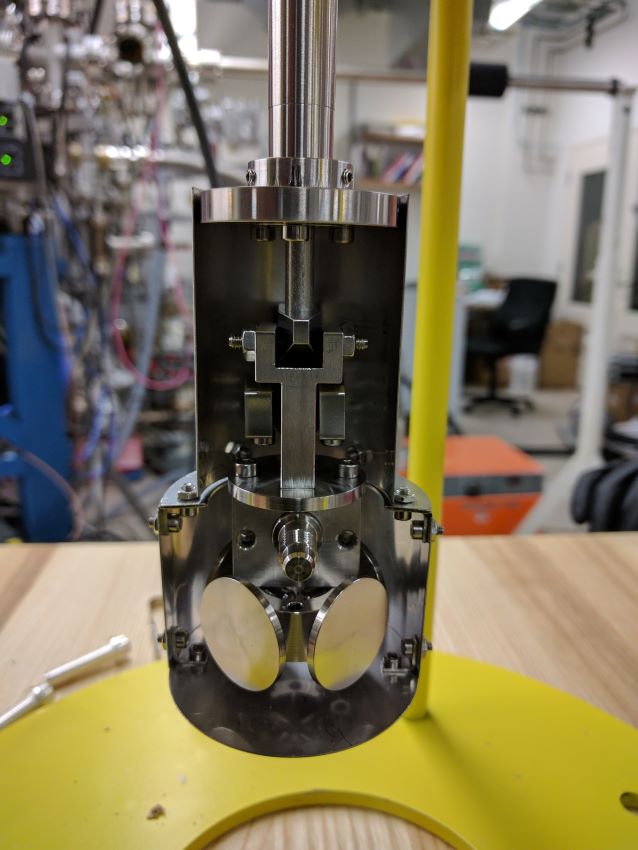

Cryopanel arrived ready to install into chamber

|

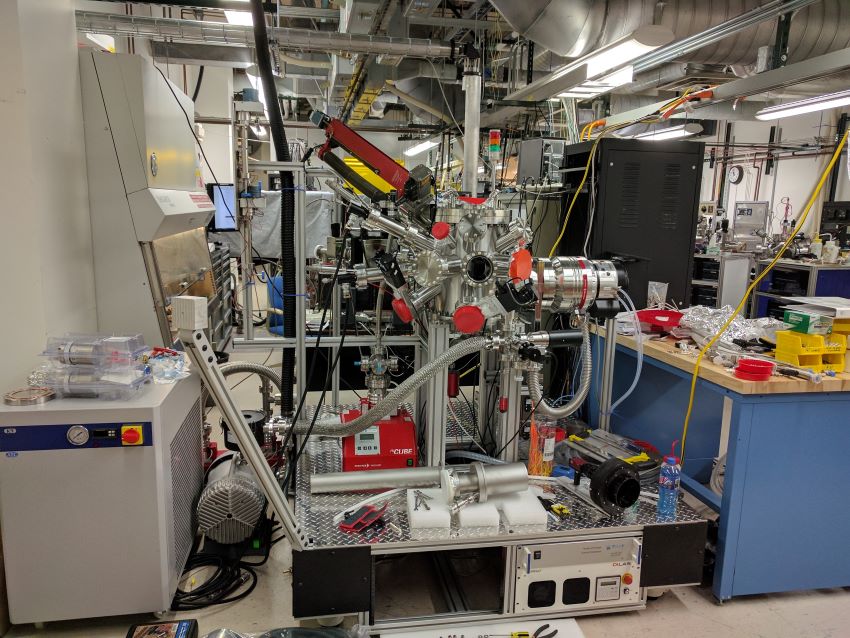

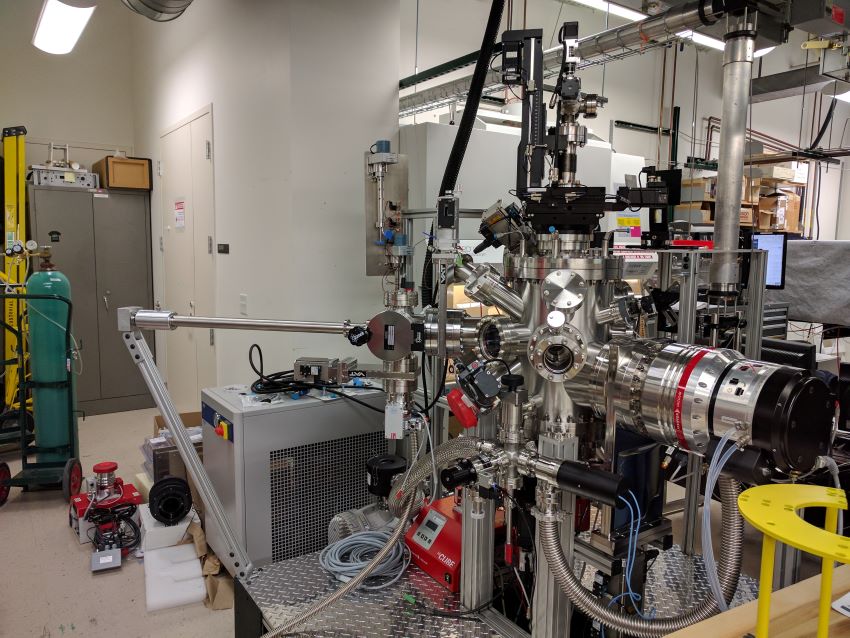

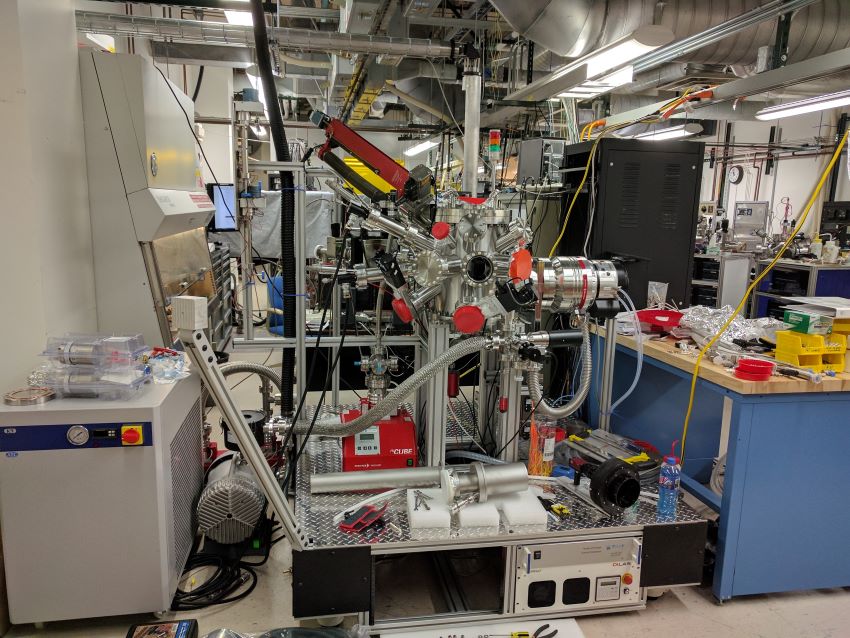

Chamber attached to beamline with gas injectors, BFM, and vacuum pumps installed

|

|

June 2017

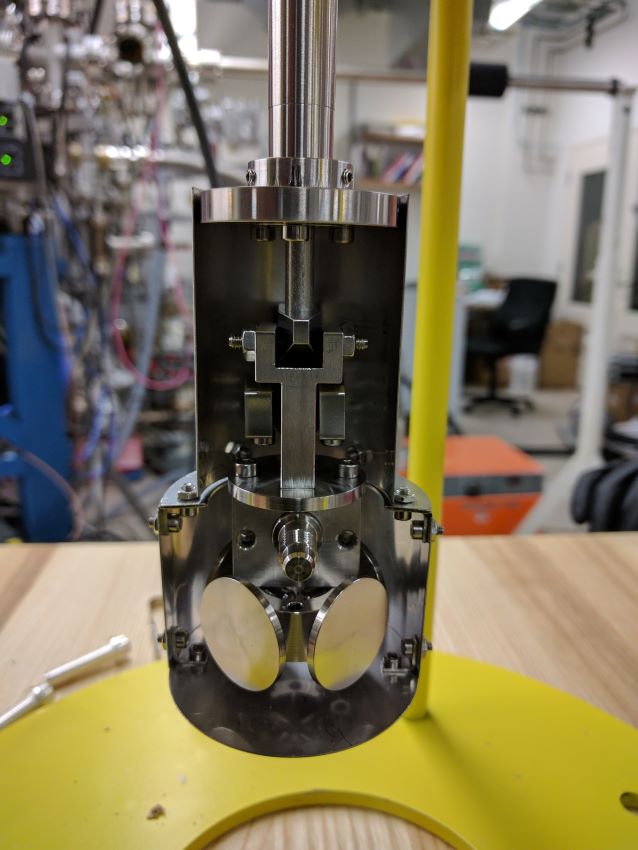

Target stage from TSST arrived

|

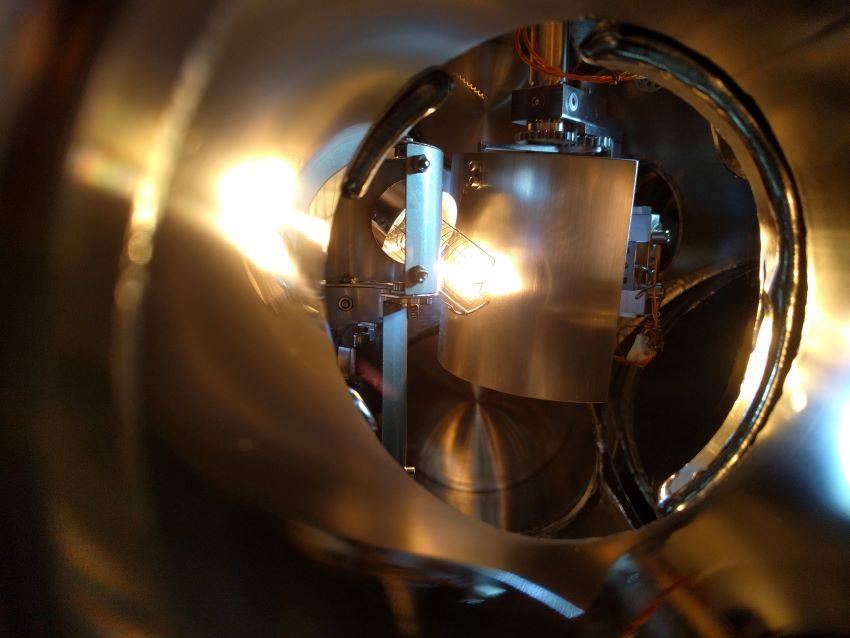

Sample and target stages installed along with the loadlock

|

Chamber completed and ready for testing. Test PLD samples grown

|

|

July 2017

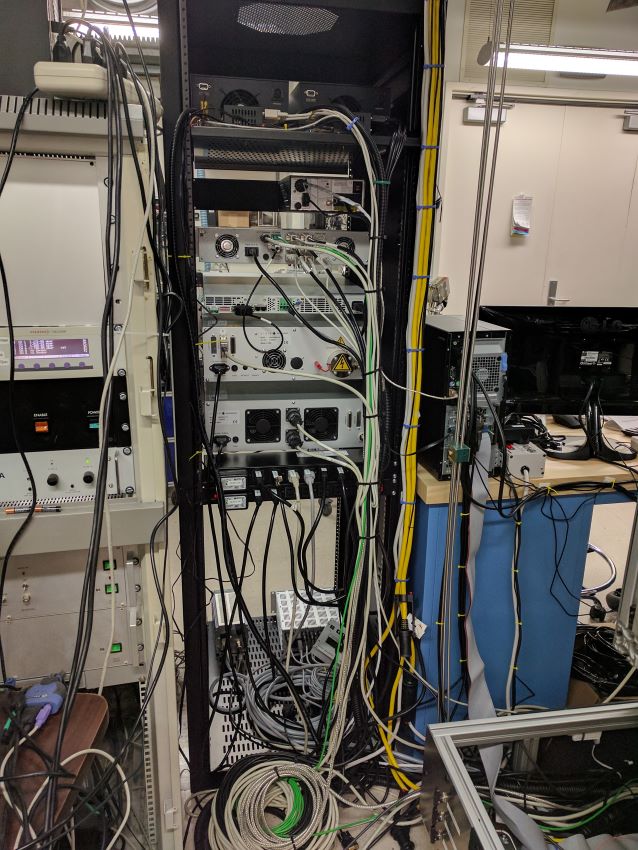

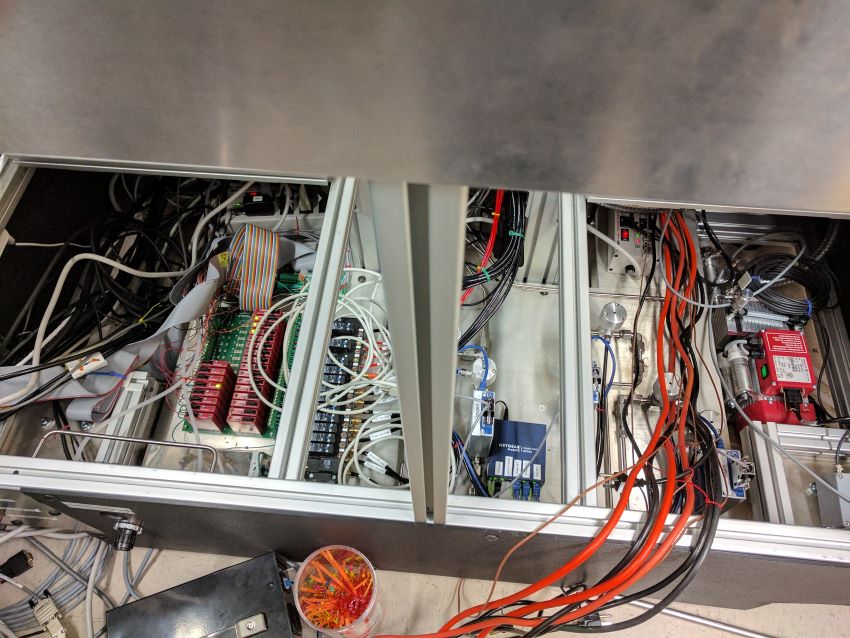

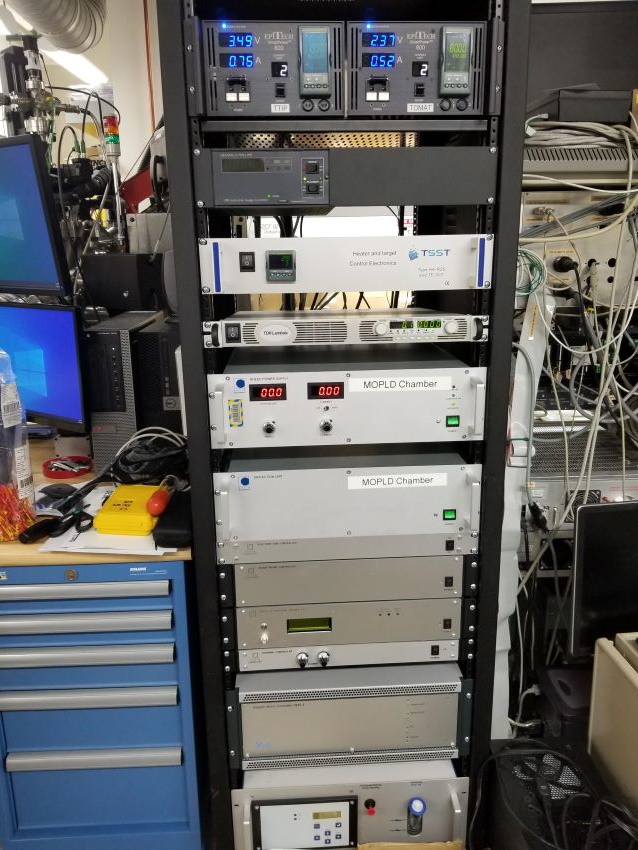

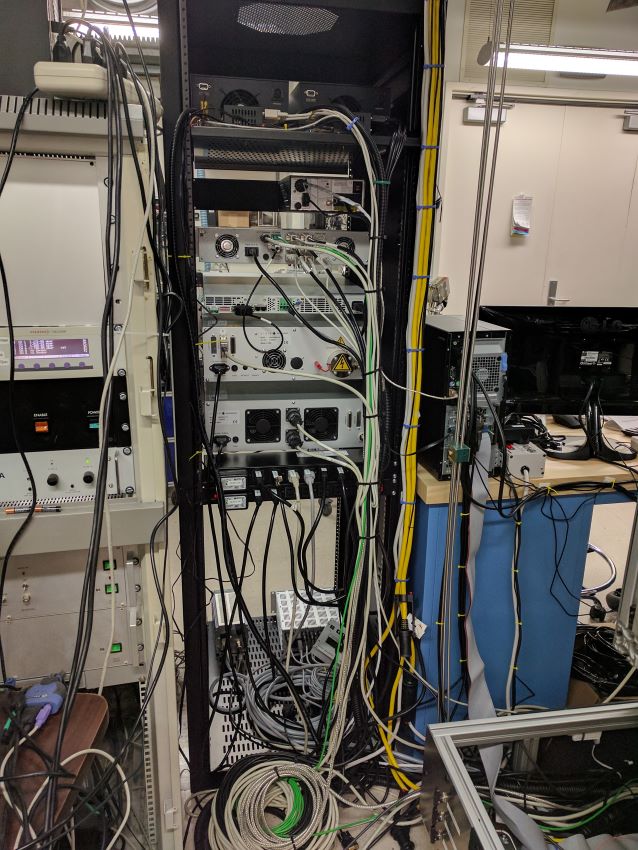

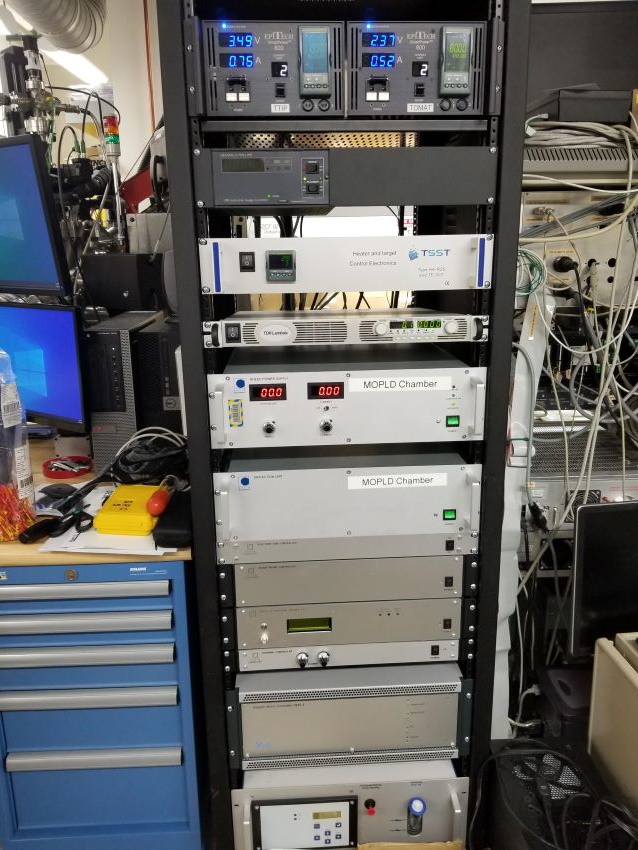

Equipment all installed in the rack. Cable organization completed

|

Chamber He leak checked.

|

|

August 2017

Installing heaters for metal-organic cylinders, lines, and injectors

|

Metal-organic gas injection system completed. Ready to grow MOPLD samples

|

|

October 2017

Using the BFM while growing

|

LabView chamber control software finished

|

|

January 2020

Staib In-situ Auger Spectroscopy/REELS system installed and tested

|

|